So why would anyone want a milling machine? If you like keeping your tools and machines for years and enjoy using old machines that are obsolete, then you really should consider a mill. The milling machine is able to remove material in 3 axis and is therefore invaluable for machining components and spare parts. For obsolete machines that will need occasional repairs, a mill is a crucial piece of equipment. When paired with a lathe, there is not much that can't be machined or repaired. In this post, I will only be focusing on manual milling machines, NOT CNC.

Parts of a mill and capacity

Before continuing, it's important for us to learn the names of the parts of mill, and understand how capacity is measured. The image below will be used as a reference:

For the head of the mill, the below image offers more detail:

It is worth mentioning at this point that the above images are of a particular style of mill that copies the Bridgeport mill. It has a knee that raises the table. There are also mills that have a head that can be dropped and raised which eliminates the need for a knee. An example of this mill style is below:

Instead of the knee moving the table up and down along a set of dovetails, the head instead is moved up and down following a set of dovetails. There are positives and negatives to each style which we will go into detail later.

In addition to the knee, there are also horizontal mills which differ somewhat to universal or vertical milling machines. In general horizontal millers are used when you really need to hog a lot of material from a workpiece and they particularly excell at cutting grooves.

In some cases you can have your cake and eat it too as there are milling machines that can be converted from vertical to horizontal such as with the fantastic Schaublin 52 and the Abene VHF 3.

With some milling machines, the table does not move in the y axis as the head is designed to accomodate y axis movement. This is the case with the Deckel FP2 as the head slides along dovetails to accomodate y axis movement:

Capacity

People often refer to the milling machine's table size when referring to the capacity such as 9 x 40, 8 x 22 etc. In this case, the table is measured in inches. This however only tells half the story as you still need to consider the clearance from the table to the column, and the table to the spindle. This will provide you with a 3 dimensional measurement of what will fit on the mill's table. To complicate this even further, you then need to consider the range of movement of the table in the x and y and z axis (see image below):

This is critical as it needs to be considered if you want to machine the full surface of a work piece without resetting it on the table.

I constantly give the following advice to those looking for machine, however people tend to ignore it. Buy a milling machine that will have a similar capacity to your lathe so it will contribute to a complimentary workshop. You really don't want to be limited by the capacity of any one machine in your workshop.

Spindle type

Although not strictly a capacity feature, the spindle taper type does limit your work envelope to an extent. If you need to change tools you may need to remove and replace tools. An R8 machine taper is longer than a 30INT for example, therefore will require more room to change which may mean having to tilt the head or removing the job from the table or vice. Examples of different spindle taper types below:

By the image you can see that length varies considerably between the various taper types. As can be expected, the more stout a spindle is, the more rigid it is. For example, ISO 40 is much more rigid than R8, however it may be more difficult to get tooling so you need to weigh up the availability, rigidity and clearance arguments when purchasing a machine.

Desirable milling machine features for a hobby machinist

Rigidity

There are many features that I believe are critical to a milling machine however as hobbyists we tend to overlook repeatability and rigidity. Rigidity is extremely important and the heavier the work you plan on doing, the more rigid you want your machine to be.

So what contributes to rigidity? The thickness of the materials in the column, the thickness of the table and the surface area of any mating surfaces all contribute to a stable machine. For example, my Jungner VF600 will be less rigid than a Deckel FP2 due to the union between the head and the column and the leverage that this union is subjected to:

Jungner:

Deckel:

This would mean that on a well designed machine, we would expect to see lower horsepower motors on less rigid machines in order to reduce stress, flex and vibration. This is the case when we compare the Deckel FP2 3 HP motor powering the spindle to the Jungner with a .75 HP motor.

As a general rule, you want the castings to be as thick as possible and any unions to have as much surface area as possible.You also want your machine to be as heavy as possible to dampen vibration and resonance.

Another feature to aid in the rigidity is the use of tapered spindle bearings. On many of the older machines spindle bearings were of the regular non tapered design paired with a thrust bearing. This meant that even a slight amount of wear would show itself in the finish. As the price of tapered bearings started to go down, more and more machines featured them as they could sustain large radial forces and act as good thrust bearings at the same time, while still being adjustable to take up any wear.

Unlike a drill, a mill often sufferes high thrust forces in the z axis in both directions plus axial forces, the abilityof the tapered roller bearings to tolerate these forces meant sustained precision over time. Anyone who has ever had an end mill pull out of a collet can attest to the forces acting on the spindle of a mill. For this reason, tapered roller bearings are pointed in towards each when supporting the mill's spindle:

Repeatability

The tolerances of a machine and the ability to lock the table and spindle all contribute to the repeatability of a machine. Since stability will also contribute to the stiffness of the column, table and head, it will also factor into the ability to make accurate passes repeatedly. Many of the European machines claimed tolerances of 5 microns or better - claims rarely made by far East manufacturers as this accuracy requires a great deal of time and cost to achieve. This can be remedied with some scraping and many have bought cheape Chinese machines and with some minor adjustments turn out very accurate work.

The backlash on the various axis of the mill will also need to be considered and accounted for in order to maintain repeatability. A digital readout helps to eliminate errors due to backlash however a DRO is not a necessity. One of the first things you should learn as a budding machinist is taking up back lash to eliminate cumulative errors.

Automatic feeds

Since a milling machine is often used to make surfaces flat and square to each other, automatic feeds are very useful as they help you to achieve a superior finish. They also mean you don't have to stand there cranking handles the whole time you are machining a large surface. Most of the smaller and cheaper machines have automatic feed in one axis, usually the x axis. If you plan on doing a lot of boring, then automatic downfeed is a very useful feature as it will allow you to achieve an excellent finish when boring.

There are various systems for automatic feeding along the x axis however in principle they function the same. The only real difference is how the speed is adjusted. Some milling machines have a motor coupled to a gearbox:

Others have pots that adjust the speed of the electric motor without the need of a gearbox:

Some machines utilize a central motor and feed shafts to drive table movements. This is the case on the lovely little Crouzet FC-100:

On larger machines, rapid table traverse is very useful to cut down machining times when you are just cutting in one direction. This is often the case if you are trying to avoid climb milling.

Rapid traverse for knee type milling machines is a very useful feature to have. Cranking the handle repeatedly to raise and lower the knee gets tiring and on long jobs, will leave you with tired arms and a sore wrist.

Quill

For those who struggle with space, having a milling machine with a quill means it can double up as a drill press. This is a very useful feature as it allows you to drill very precise holes that you can then enlarge with a boring head. Machines without a quill will require the whole head or knee to be moved in order to bore a hole which is far less convenient than a quill. The other advantage is that if you have automatic downfeed, you can do very heavy drilling operations without having to stand there for extended periods pulling on the quill handle.

Head tilt

The ability to tilt and "nod" the head of a machine makes it more flexible for complex milling jobs. Many machines have the tilting function but far fewer can nod the head. Some of the Bridgeport models have this feature and although it is infrequently needed, it can be a life saver and save having to set up your job repeatedly:

As a potential mill owner you need to keep in mind that everytime you mess with tilt or nod, you will need to tram your mill's head again.

Tramming is when you set the head to be at exactly 90 degrees to the y and x axis. Failure to tram the head will leave you with a range of issues ranging from poor finishes to work that is cut at any angle other than that you are shooting for.

Column type

Since we are breaching the topic of tramming, it is worth talking about the column types found on milling machines. Many of the far East machines are built to a budget and feature a round column:

This column type can be a challenge to tram and keep trammed if it lacks a keyway. Under heavy cuts it is often the case that the head will move relative to column, throwing out the tram. To remedy this, many manufacturers are now starting to make their mills with square columns or with dovetails like the Sieg X3:

This tends to be more of an issue with the smaller machines, usually bench top milling machines. However, I do have to emphasize that any mill is better than no mill at all. If you don't have a choice, get what you can then upgrade later.

Power

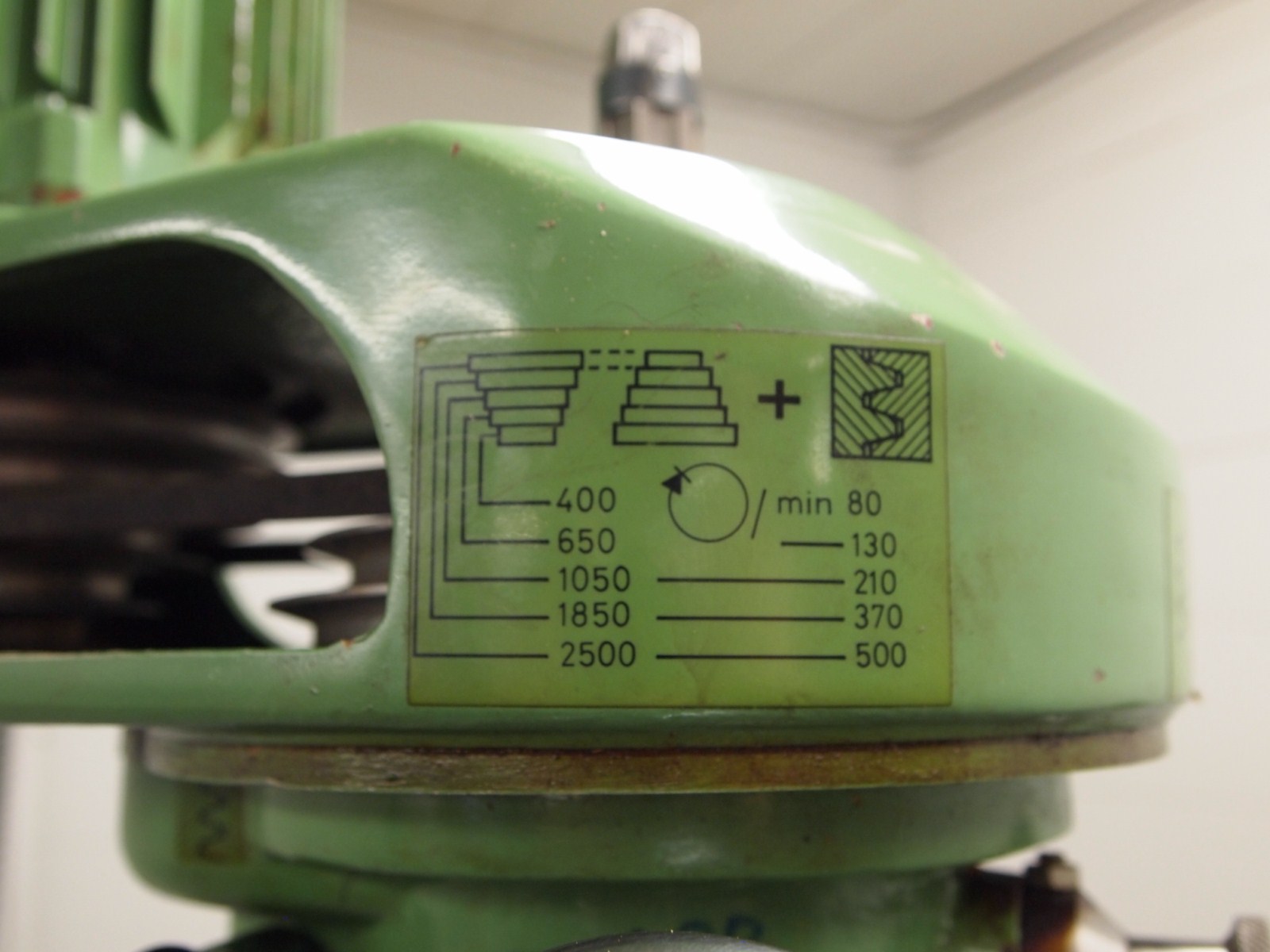

The power rating of the motor only tells a part of the story with milling machines. The power of the motor is calculated as the toque multiplied by the rotational speed of the axis. If you will be taking heavy cuts with large cutters, then you want high torque and lower speeds. Often, a good gearbox with a wide range of speeds or the same with pulleys is more important than the power of the motor.

So what speed range should you be looking for? I think a useful range should include an rpm below 100 for threading and large drilling, to around 2000 for smaller end mills.

This however is less important if you have a 3 phase machine as with a VFD you can slow down or speed up the motor by adjusting the incomping electrical frequency - this however comes at a loss of torque.

So this poses a question. What is better, belts or gears? I really don't think it matters too much with regards to reliability of the machine. There are some pros and cons of each type of head. Gears can handle higher torque but can be noisy. Belts can slip at higher torque but this is also an insurance policy as a slipping belt is nowhere near as big a problem as a gear that is destroyed by too much torque. I personally like belts because I have a small workshop and like machines to be quiter. Belts are also cheap to replace and require no maintenance.

Some milling machines have stepless variable speed heads. This is a feature found on the Bridgeport and means that speeds can be adjusted on the fly. This is usually achieved via a set of cone pulleys that expand and contract to adjust the speed:

It's very handy and I can attest to it's usefulness as my Chipmaster lathe has this feature.

3 phase motor

With the relative cheap price of variable frequency drives, 3 phase motors are no longer the headache they once were. If you come across a good machine that is 3 phase, don't be put off. As long as your home circuit can handle the current requirements, then all you need is a VFD. The advantage of a 3 phase motor is that it will often have reverse and will operate much smoother than a single phase motor.

Lubrication

On the more expensive machines, you will often see one-shot lubrication included as standard. This feature allows you to pump a plunger and distribute oil to all the necessary oiling points around the mill quickly and efficiently.

Although not a necessity, it is a useful feature when you consider that many milling machines have at least a half dozen oiling points. A poor lubrication regime is death to machine tools and as a general rule, your machines should be dripping oil. Too many people are penny poor and pound rich when it comes to lubrication. Oil is the cheapest thing you can buy that will ensure a long service life for your machine. Don't try to economize on using oil for your machine! Use the recommended oil and be careful of synthetic oils that contain sulfur. Sulfur will bond to yellow metals like bronze and rather than the sulfur breaking away under use, it will actually remove the foundation metal, erroding away the metal.

Handwheels

A nice feature is to have handwheels at each end of the table. This is quite handy when you want to avoid getting hit by hot chips or to observe a cut in progress.

Micrometer dials

This is redundant if you have a DRO or plan to install one but large, clear micrometer dials are a big plus on a mill. I don't have a DRO and only use the dials so I appreciate the large, satin chromed dials on my milling machine.

Coolant system

If you plan on doing serious machining work on your mill then you should consider using coolant. It extends the life of your cutters and contributes to a better finish. The lack of a coolant system is not a deal breaker as it can be added as an aftermarket item however it is nice to have. There are different types of systems.

Flood coolant:

Fog coolant:

There are advantages to both types however for many home shop hobbyists coolant is extra hassle and mess. I fall into this category and as such do not have coolant on my lathe, mill or bandsaw.

Useful accessories for a milling machine

Often when you are buying a machine you have the usual box or two of odds and ends that follow. Don't overlook the inclusion of these accessories since buying them seperately quickly comes to a large, difficult-to-justify figure. So here is a list of accessories that I think are very nice to get with your mill.

Collets and collet chuck

No matter what mill you buy, you will likely end up needing a collet chuck and collets. Collets allow you to accurately clamp cutters and accessories of differing sizes just by changing out a collet. If you are looking at an older machine or a machine with an obscure spindle taper, this accessory can mean the difference between purchasing the machine and walking away. Most modern spindle tapers utilize ER collets such as the ER32 collet:

Drill chucks

Good quality drill chucks like Albrecht and Rohm cost a great deal of money. Always check to see if these are included as they are an extremely handy accessory, especially if your mill has a quill.

A good German drill chuck is a thing of pure excellence, not to be compared with a cheap Chinese copy.

Rotary table

In my opinion a rotary table is a must have accessory for a milling machine. It allows you to clamp your workpiece then rotate accurately in order to drill holes, enlarge hole, cut arced slots etc. It opens up the possibilities significantly for your mill.

Just be aware that when considering tooling and work holding for your mill, the lower profile accessories are often better as they don't interfere with tool changing or capacity as much. As with the example above, many rotary tables can be used flat or stood up at 90 degrees to function as a dividing head with the inclusion of a chuck or tailstock. Regardless of how you plan to use the dividing head, having the full range of dividing plates and the tailstock will open your options. The dividing plates are useful as they have different hole counts that help you calculate angles quickly and when used with a dividing head allow you to cut gears.

Rotary table / dividing head:

Dividing plates:

Tailstock:

In use for cutting gears on a flywheel:

Dividing head

Rotary tables and dividing heads are often one and the same thing. By adding a chuck to a rotary table you can have a dividing head. This is the case with a dividing head I have recently ordered:

Here you can see that it would function as a rotary table as well, allowing work to be clamped using T nuts.

There are however dedicated dividing heads and these often allow you to adjust the angle of the work and it's rotation but are not well suited as a rotary table given their high profile:

Digital read out

In this day and age of new fangled digital gizmos, you can't look past a digital read out or DRO as they are known. A DRO is basically a digital representation of the position of your spindle. Many DROs have additional functions that allow you to calculate hole spacings or arcs. They eliminate the need to read the dials and also help eliminate errors due to backlash. They elso make life easier for those of us who's eyesight is not what it used to be:

There are 2 main types of scale used along the axis to establish the measurement. Glass scales are the older technology and are more prone to errors from wear and coolant however are generally cheaper. Magnetic scales are more reliable and their size can be adjusted just by cutting them shorter however they are more expensive.

As is often the case with used machines, not everything works as it should. Be aware that on older DRO units that you may not be able to find replacement scales as the plugs or communication protocol may have changed over time.

Dial test and dial indicators

Measuring tools are an essential part of machining and without them, even a man on a galloping horse will notice the poor fit and finish of your work. Necessary for tramming your mill and your vice, they are absolutely essential and if you can find a mill with the measuring equipment included, then this is definately a deal sweetener:

There are many different brands but some good ones are Somet, Mitutoyo, Starret and Noga. There is also a lot of specialized measuring equipment you can buy however dial indicators and dial test indicators are essential.

Vice

The milling vice is the go-to work holding for the milling machine. There are several versions of the milling vice. You have the precision milling vice:

The hydraulic milling vice that provides higher clamping forces through a hyraulic compression unit often in the handle:

Then there is the screw type vice that relies on the acme screw for it's clamping pressure:

Oil cans and pumps

Something I like to see with every machine I purchase are the oiling accessories. Be wary of machines that don't have the equipment at hand or have oiling points painted over or filled with grime. There are a range of different oil fittings like zerk:

Ball oil fittings:

Of course having a large box of endmills, parallels, indexable tooling and universal boring heads is also nice but this equipment is usually not sold on as it is often kept by the seller or bought early by family friends. If you are lucky enough to get a lathe with everything included then you are luckier than I have been.

Well that is about all I have the energy to write on the topic of selecting a milling machine for the hobbyist. I hope you found this useful and I wish you all the best in purchasing your new machine!