Here she is:

Swing over bed: 5.75" (146 mm)

Distance between centres: 20" (508 mm)

Bore diameter: 1 5/16" (35mm)

Speed range: 35 - 3000 rpm

Weight: 550 kg

Power: 3 HP

Starting at the Tailstock

I guess the best way to review a machine is start at one end and move through to the other. I'll start with the tailstock and the very end.

As you can see, the tail stock is very heavily constructed. Mine has both metric and inch graduations. The dial is very large in diameter and is satin chrome finished like all the dials on the Colchester Chipmaster. There are 2 levers, one to lock the tailstock quill, the other to lock the tailstock to the bed.

As is evident from the picture above, the bed is very wide given the modest capacity of the lathe. It is very stable and the tailstock is no exception. The lathe features several lubrication points for the ways on the carriage, unfortunately there are none on the tail stock.

The Colchester Chipmaster Bed

An exceptional feature of the Colchester Chipmaster is it's bed. Extremely rigid and well thought out, it really is the crown jewel of the lathe. It features hardened ways and eleptical holes that allow the swarf to fall through to the rear of the machine.

This feature makes cleaning the machine a snap as there is even a hole directly below the chuck.

A quick brush pushes the swarf to the chute and to the back of the machine.

The Colchester Chipmaster Carriage and Apron

The carriage of the Chipmaster seems strange to many due to the carriage hand wheel location. On most lathes, this wheel is set up so that it is operated by the left hand. On the Chipmaster it is the opposite.

To be honest, I have found this to be quite convenient and have had no issue with it at all. Eagled eyed readers will notice that this machine does not have a thread dial indicator. The Chipmaster Continental does not have an indicator, and it is expected that you will use the machine's reverse to keep the leadscrew half nuts engaged when threading.

Between the two hand wheels on the apron is the feed shaft lever, used for longitudinal and cross feeding. To the left of that is the lever controlling the half nuts for the lead screw. The fact there is a lead screw and separate feed shaft makes this machine a lathe capable of heavy work while still saving precision for when it's needed.

The carriage is locked via a nut at the top of the carriage, located next to the carriage's oil bath filling hole.

A permanent lever would be ideal here however given the low clearance with the compound slide it would be hard to do right. I leave a spanner on it permanently. You can also see the oiling point for the ways. The cross feed and compound slide have generous dials and are extremely easy to read.

The longitudinal feed and cross feed are a combined unit located on the front of the apron. They are combined into a knob that is slid into position. The first notch in is for cross feed, 2 notches in is for longitudinal feed.

Atop the compound slide is the quick change tool post. On my machine I had the Dickson style. It is very decent quality and rigid. I have taken some deep cuts with it and have had not had any problems.

On many Colchester Chipmasters the way wipers are long past their due date. You can make Chipmaster way wipers easily by cutting 4mm neoprene or any other oil resistant rubber to size. I used a bandsaw and razor to cut mine. I made a template for them so I never have to measure again, just transfer the outline onto the rubber and cut away. You can see by the picture below that the fit is tight:

A useful extra is the carriage stop. This needs to be used with caution though as on occasions the carriage has pushed the stop and I have come close to crashing the machine. The standard stop has 6 different settings and is useful for work that is repetitious.

Colchester Chipmaster Headstock

There is not really a lot to be said about the headstock. It features Gamet precision tapered roller bearings and has a spindle size of 35mm - quite generous really.

The headstock is attached via 4 Allen head bolts. I initially thought this was flimsy but the finishes I have obtained from the machine have proven me wrong. The chuck is attached via a D1 - 3 cam lock. This ensures that the chuck stays on when you spool the machine up to 3000 rpm. Just check that all lugs are tight before testing it out or risk a 4 kg missile tear through the garage, your neighbour's house and the farmer's prize cow... 2 km away.

The headstock is where the beauty of the machine's design shines through. It's a terrible state that modern design has evolved into the monstrosity it is today. The 60's is where it was at. The art deco style of the machine make it as nice to look at as it is to use.

The headstock features 2 levers on the front. The lever on the right is the clutch lever, and the lever on the left is the belt / gear selector. The lever at the back is for the electrical box - right is forward, middle is off, and left is reverse. You will also find the headstock oil filler at the back.

For the low rpm, high torque applications, the gears are engaged by lifting the leaver up. When this leaver is engaged, beware!!! There is 3HP turning that spindle. A man can resist about 1/10th of a HP so it will easily tear your arm from it's socket if you are silly enough to use the machine with a ring or watch. When the cover is open you will also find the gearbox oil filler.

Colchester Chipmaster Continental Gearbox

The continental has a different gearbox arrangement than the imperial model. It features a joystick design with 6 different positions.

The joystick is the lever on the bottom right. The lever above it is for the carriage direction and the lever to the left above the oil sight glass is to allow more options for threads / feeds. There are a large number of threads available if you have the change wheels. I was lucky enough to have received a complete set with the machine.

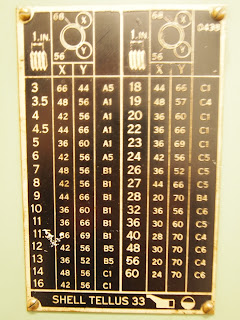

The charts for feeds and threading have been included below:

I have found the arrangement of the controls to be quite intuitive and easy to understand. With the A, B, C lever, belt and gear head lever and the joystick, you have a combination of 44 threads and feed speeds available with the 28, 68 and 48 tooth change wheels.

Colchester Chipmaster Speed Wheel

The Chipmaster features a Kopp variator, a device that allows stepless speed changes on the fly. It is purely mechanical and is a marvellous invention really. Many Chipmaster has noisy variators because people didn't want to spend the extra time or money to either top up the oil, or purchase the right oil from the get-go.

Below you can see that the machine had the Swedish translation of "slow" and "fast" put on it from factory. Quite impressive really considering it was built in 64.

The speed wheel controls the variator via planetary wheels and by pulling the handle out while the machine is running and rotating left or right, the wheel will indicate what rpms you are running at. This system is very easy to use and is quite useful when you are whittling away a large diameter piece. As you reduce the diameter you can increase the rpm - the same applies to parting stock.

Upon opening the door, it is evident that the machine features the newer variator and bracket. This is quite strange as the clutch lever is from the old design. The variator is NOT sealed. If you over fill it like I did, oil will pour out of the output shaft and onto your garage floor, hence the drip pan in the photo.

You can see that the variator bracket is isolated via rubber mounts and that the gearbox is belt driven from the variator. This combination greatly reduces vibration and improves the surface finish by a number of magnitude.

Colchester Chipmaster Change Gears and Clutch

The Chipmaster was made as a toolroom lathe. Despite the norm of tool room lathes weighing at least 1000 kg, this lathe had the rigidity and speed range to handle both heavy and delicate work. The change wheels allowed the machine's capability while keeping it's weight down as a comparable gearbox lathe able to do the same would push it's weight into the Monarch territory.

Upon opening the cover a micro switch cuts out the magnetic power switch. You quickly notice the Matrix clutch that allows you to engage and disengage the spindle - making metric threading possible.

This by the way, is a feature every serious hobby machinist needs to experience. Once you have used a lathe with a clutch, it is very hard to go back.

You will also notice in the above photo that there is a belt that allows the spindle to be run directly from a the clutch, which is run via 2 vee belts from the variator. For speeds over 350 rpm, the belt is engaged, while the gears are disengaged. This allows you to attain the extremely smooth finishes the Chipmaster is famous for.

From the end view you can also appreciate just how large the spindle diameter is.

Colchester Chipmaster Cabinet

The Chipmaster has some storage, but don't expect to be overwhelmed. The cabint at the front can be removed and actually allows easy access to key parts of the variator and motor.

Colchester Chipmaster Art Deco Design

Upon closing the gear cover, you are left with this view:

The Chipmaster may not be a Monarch, but it is a beautiful machine. If you have the chance to buy one that is not worn out, do it. I paid more than I wanted to but have not regretted it one bit. It is as functional as it is beautiful and really is a great machine to run. If you are looking for more info on oils, then look here:

Which oil for Colchester Chipmaster?

For information on the Chipmaster:

Chipmaster Info at Tony's Site

And now for one last picture...

BEAUTIFUL!!! Well that is the end of this novel. I hope you enjoyed it and if you are looking at buying a Chipmaster or are a fellow owner, drop me a line.

Stay safe.

HELP! I was wondering if you could help me out. It seems you have a great knowledge of these machines. I have just acquired a Chippy, an imperial model. I cant locate or work out how its supposed to reverse? It doesn't have the reverse lever at the back of the headstock like yours has? Can you advise me at all? sapwood@hotmail.co.uk

ReplyDeleteYou likely did not pay over the odds. Looks like the original paint and difficult to tell but there does not appear to be the general rash that appears on the top of the apron and the compound slide found in well used machines.

ReplyDeleteI own two of these, one from 1958, fairly good condition college machine. I used to use it as a student at the now closed engineering department, bought it in 2000, used it in the mid 70's myself at that college.

The other I bought at auction recently, it is from 1976 from a defunct engineering company. Though clean I would say it is in no better or worse condition than its predecessor of 1958.

Earlier has 3 ball variator and later the 6 ball version. Both are quiet so I will keep them for now so that I have the low speed grunt. The oil for those variators is a stinger, nothing less than 20L available as you have found, about £90 delivered.

Reason for buying a second same model was to have enough parts to see my usage through my lifetime. I am 55 years old and barring some gearbox or crash catastrophe I should keep a working machine for the rest of my days.

For the money these are incredibly good machines. For what I paid for my two machines I would have to add another £6,000 for a Monarch or £4,000 for a Hardinge, not interested as I need my £ for other things.

People who favour the equivalent Harrison machines have no idea what they are missing. Surface finish from a Chipmaster is superior side by side with a Harrison that has been similarly maintained.

Dear Axeman,

ReplyDeleteI have a problem. I have been offered to buy a Chipmaster and I am going to have a look at it tomorrow in Sweden. I must however decide then and there. What should I look for? Any tips? What usually wears out on the Chipmaster? I would be extremely thankful if you could drop me a line at temp2@magnuslord.se. Many thanks, Magnus

Please Admin,

ReplyDeleteQ.Explain the control system of servomotors and operation of hand-wheels in lathe machines?

What is the price of this machine ? is that for sale ??

ReplyDeleteI served my apprenticeship with Colchester Lathe Co. 1965-72....

ReplyDeleteHello, ran across your blog looking for info on Chipmasters. Nice machine you have. Mine was not in such great shape when I got it. Your pictures are great (I’ve scoured them all), but I can’t quite get details on something. Do you have a picture of that bolt/stud that the splash guard connects to on the headstock near the chuck? Mine is missing and my splash guard doesn’t stay up. I can make a replacement, but would like to keep it original. Second and last thing: your steady rest. Would you be so kind as to take some detail pictures, maybe with a ruler in the photo? I don’t have one, but can cast/machine replacement parts to make one match the original closely. If you’re willing to help, I can send my email. Many thanks.

ReplyDeleteHello

ReplyDeleteConsidering buying a Chipmaster and found your review online while doing some research on them, thanks for the review and great photographs, it may help make my mind up.

The one I'm looking at is I think a 1968 model and looks to be in lovely condition from the photographs, although is a little on the expensive side.

Best wishes

Steve

Nice review of your Chipmaster!

ReplyDeleteI have a '76 Chipmaster Continental version, not in a bad shape but not so well maintained like yours. I'm currently trying to replicate the feed and speed plates because my lathe came without both plates. till now I used your pictures if I have to change gears.

One of the hurdles to take is to find the right size for the plates, could you help me with that and meassure both plates?

Your help will be greatly appreciated :-)

Best regards,

Rik, a fellow Chipmaster owner.

Hello,

ReplyDeleteCan you please let as know what oil to use?

Also when I try to change speed the hand wheel spind but the speed stay the same.

Please help

Thank you,

For info on Colchester lathes, current owners have a discussion group at https://colchesterlathe.groups.io/g/main

ReplyDelete